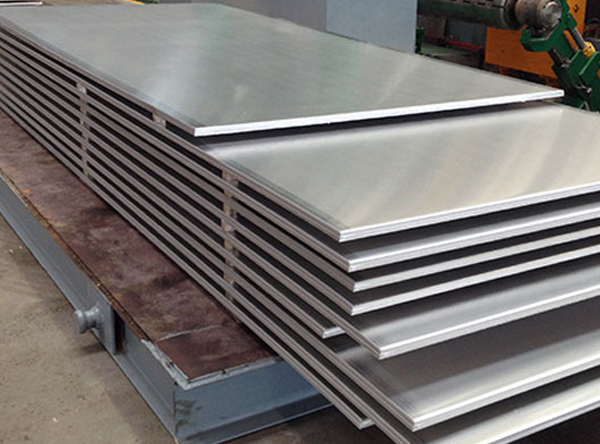

AISI 410S

Stainless steels are high-alloy steels with good corrosion resistance due to large amounts of chromium present

in them. Most of the stainless steels contain about 10% of chromium.

Stainless steels are available in three different groups based on their crystalline structure. These groups

include martensitic, austenitic and ferritic. The combination of martensitic and ferritic steels forms a

fourth group of stainless steels known as precipitation-hardened steels.

Grade 410S stainless steel is a non-heat treatable version of grade 410 stainless steel.